Value Creation

Electronic Device

Business Segments

Segment Overview

One of the biggest strengths of this segment is its extensive lineup of semiconductor devices used in high-voltage and high-current controls. Diodes, one of our mainstay products, are used in power supply for automobile components, industrial equipment including factory automations and robots, as well as home electronics. MOSFETs, a type of switching device, are used in motorcycle ECUs in the Car Electronics segment as well as in other components for the industrial machinery, home electronics and mobility markets. We also supply power modules for industrial machinery and automobiles, power ICs (integrated circuits) for lighting, and other high-performance products.

Percentage of total net sales (Fiscal 2020)

|

Net sales |

36.3% |

■Progress under the Medium Term Business Plan

| Opportunities | Risks |

|

|

1. Enhance the competitiveness of mainstay products

Improve productivity: While maintaining a commitment to in-house design, we are proactively advancing considerations of external contracted production for mainstay products that have conventionally been designed and manufactured in-house (such as diodes and MOSFETs)

Accelerate development of high-voltage, high-current products: We developed and released products that effectively align Shindengen’s technologies with consumer perspectives to offer higher value. These included (1) low loss, high lightning surge protection capacity bridge diodes for major home electronics, which are increasing in functionality, (2) diodes that are guaranteed to function at high temperatures for the power supplies of high power consumption data center servers and (3) high-density, high-capacity diodes offering voltage specifications that were previously impossible in compact packages. We also expanded our lineup of products that meet the AEC-Q101 reliability standard for electronic components used in automobiles, a category that is expected to grow.

Other: We expanded our lineup of compact power MOSFETs using new internal structures to meet growing needs for size reduction and higher efficiency in electric systems for automobiles. Furthermore, we released unique new products, such as an ideal diode IC, an alternative to diodes for cases that demand circuit design that is even more space-saving and low loss.

2. Develop growth businesses

Reinforce power modules: We are expanding our lineup of compact, lightweight products, mainly for the mobility and industrial machinery markets, to meet growing needs related to power modules. In addition, we are considering external contracting options from the perspectives of manufacturing cost, production capacity, and development time, with an eye toward realizing product development that is better aligned with customer needs.

Improve the competitiveness of power modules: We merged the operations of domestic production lines with high-productivity lines employing IoT technologies in Thailand to advance rationalization and improve productivity.

3. Create next-generation products that are a decade ahead

Develop post-silicon devices: We are advancing the development of power semiconductors that use beta-gallium oxide as new option for next-generation devices.

R&D

In diodes, we advanced development of industry-leading low-VF bridge diodes and world-leading high lightning surge protection capacity bridge diodes. We also continued basic development of semi-insulating layers, an elemental technology for new diode structures, and glass printing technologies.

In MOSFET products, we advanced product development of Nch low-voltage and Nch high-voltage MOSFETs using new structures. We also advanced product development of 650 V and 1,200 V SiC MOSFETs and began development of Pch low-voltage MOSFETs, a first for Shindengen. In packaging, we completed the development of a 5x6 mm package with two independent elements that offers size reduction, higher current and higher quality.

In power modules, we expanded the range of modules under development, focusing mainly on general-purpose products for mobility and industrial machinery applications. We also worked to reinforce custom product development for mobility using proprietary Shindengen technologies. In addition, we advanced development of modules using high-current and high-frequency SiC MOSFETs and GaN HEMTs and began supplying samples to a wide range of customers.

In IC products, we commenced development of ICs for the mobility market. Leveraging our circuit design technologies, we contracted out operation of our fine patterning production lines to advance development of ICs that will be competitive in terms of functionality, quality and cost.

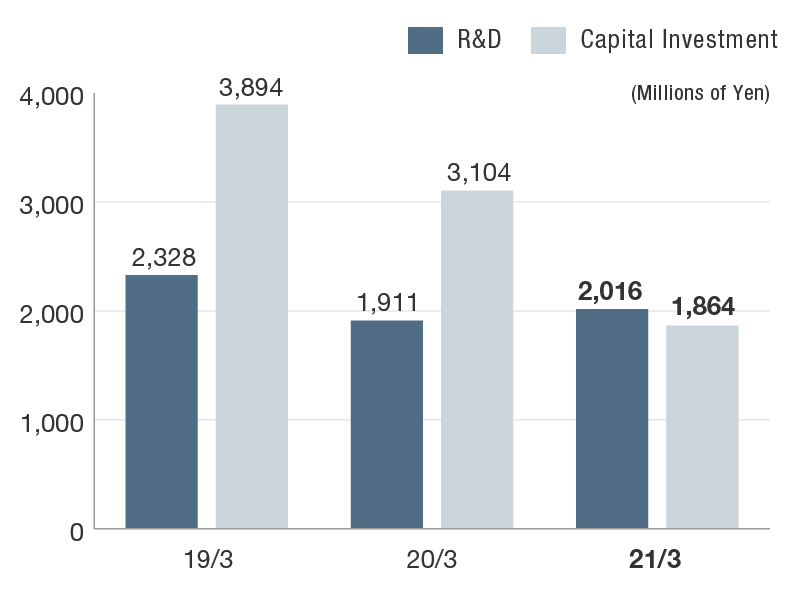

R&D expenses in this segment came to ¥2,016 million.

* SiC stands for silicon carbide, and GaN stands for gallium nitride. Both are next-generation power semiconductor materials.

Capital Investment

Segment capital investment totaled ¥1,864 million. Capital spending went mainly toward expanding production capacity and upgrades at Akita Shindengen Co., Ltd. and Lumphun Shindengen Co., Ltd.

R&D and Capital Investment

Highlights

Developing Ideal Diode ICs

In step with the evolution of computerized technologies in devices used in automobiles in recent years, the number and range of applications of electronic control units (ECUs) used on vehicles to control their electronic devices are increasing.

The electricity that powers these ECUs is supplied by batteries and DC/DC converters in the vehicle. Diodes have conventionally been used at the power input to ECUs to protect them from reverse current. However, function integration and increasing multifunctionality has led to the use of higher currents, increasing the importance of heat dissipation measures, which has in turn impeded device size reductions.

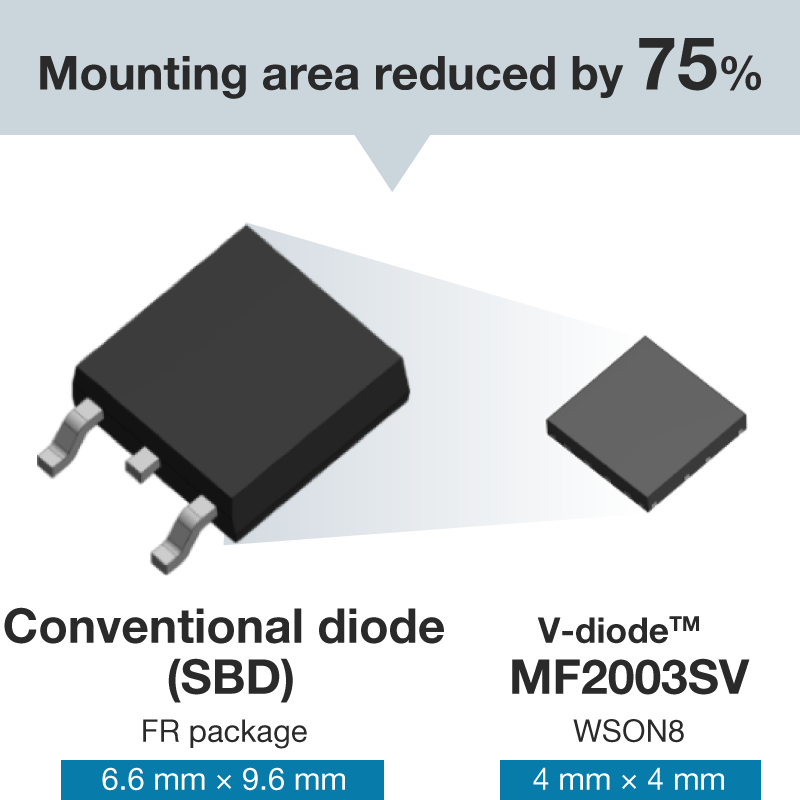

To address this issue, Shindengen developed the MF2003SV IC V-DiodeTM ideal diode, which combines reverse connection protection with a MOSFET.

By replacing conventional diodes with a Pch MOSFET, the use of this product reduces conduction dissipation by 55% and achieves a major reduction in temperature increases of 37%. This enables the simplification of heat dissipation measures and reduces the mounting area by 75%, contributing to device downsizing.

In addition, this product incorporates a MOSFET drive circuit, eliminating the need for external parts and thereby contributing to simplified circuit design.

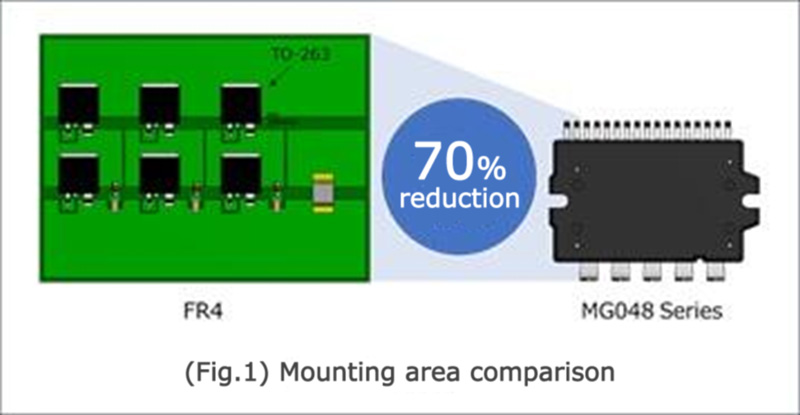

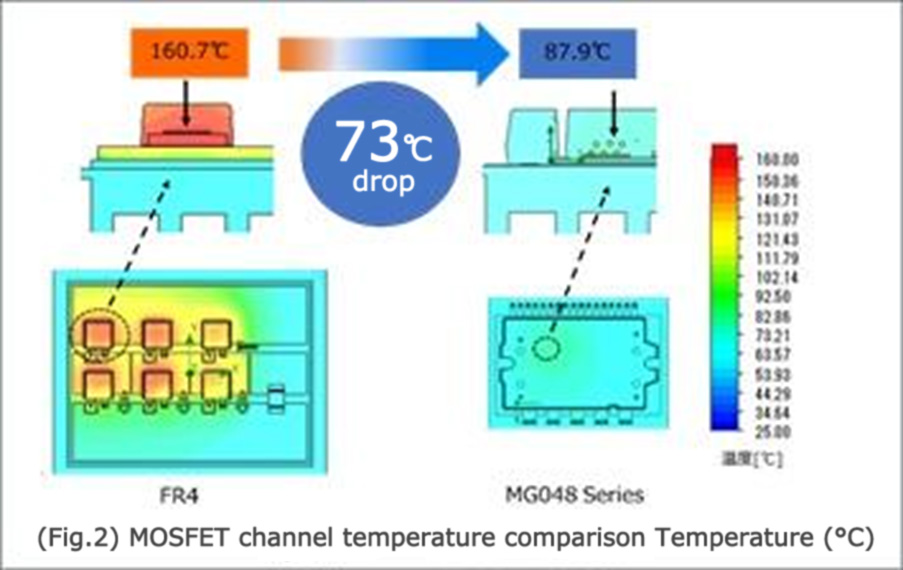

Power Modules for Motor Drive Systems

The shift towards electrification and higher performance for vehicle control systems is accelerating. However, this has led to concerns over the increase in the number of components and growing size of ECUs of such systems. In light of these issues, in the area of electronic power steering (EPS), we are working to improve fuel efficiency and decrease weight and size through electrification.