- TOP

- Lineup

- Bharat Mobility Global Expo 2025

- Power Module

Power Module

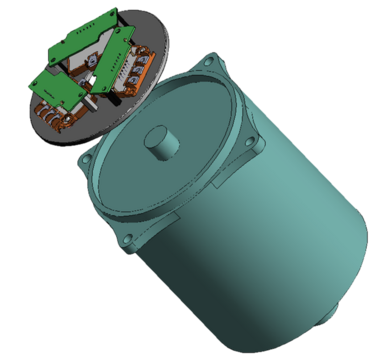

Invertor Integrated Motor Powered by MODULE

Features

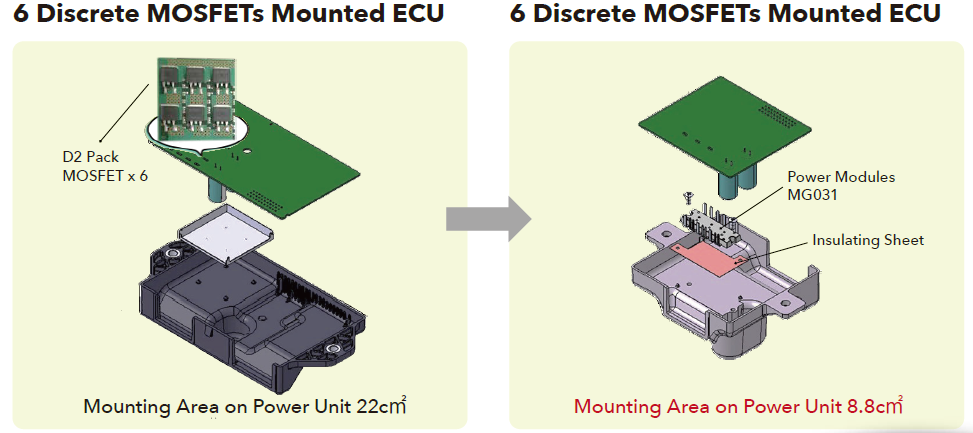

①Built-in Shindengen’s Power Module

Shindengen's power modules can achieve the same performance in a smaller area than MOSFETs implemented as discrete components, contributing to product miniaturization.

②Streamline Assembly Process

Power module solution can streamline mounting/assembly process and no insulation is required on each chips.

③High Heat Dissipation

Insulation layer and Cu substrate can achieve heat decentration and dissipation.

Concept Model for Automotive Mechatronics

Please feel free to contact us if you have any request for changing specification or adding optional feature.

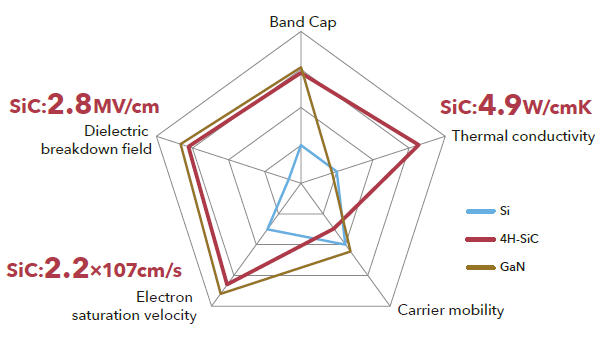

SiC Power Module『MG074』

SiC VS Si

- High Voltage & Low Loss

- High Speed Operation

- High Temp. Operation

Features

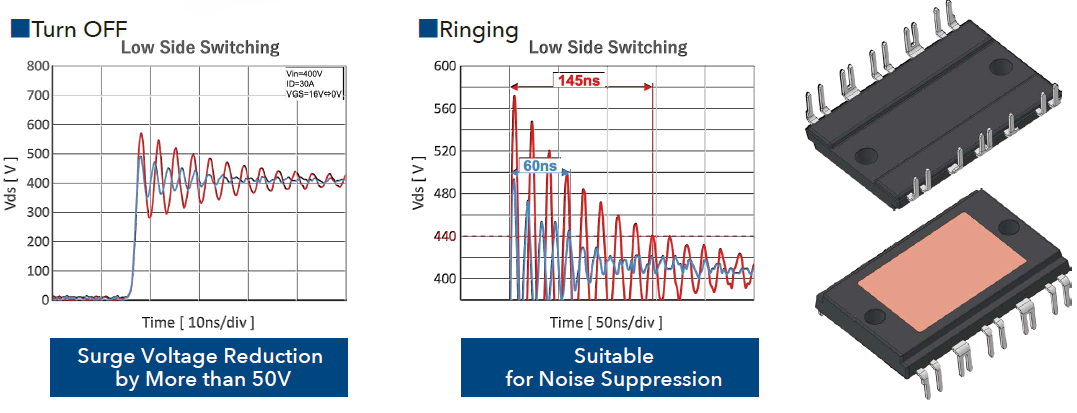

①High-Speed Switching & Low-Noise Performance

Low stray inductance by our proprietary packaging technology can improve switching performance and suppress noise generation.

②Low Inductance Structure

Terminal and pattern layout inside the module can reduce stray inductance by 66% compared to using two discrete components.

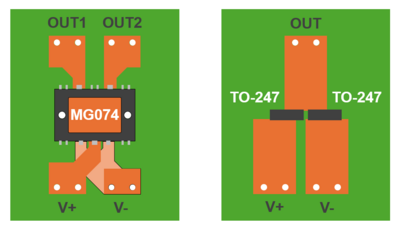

| SiC Module | TO-247 4pin | |

| Measured Value | 7.24nH | 21.48nH |

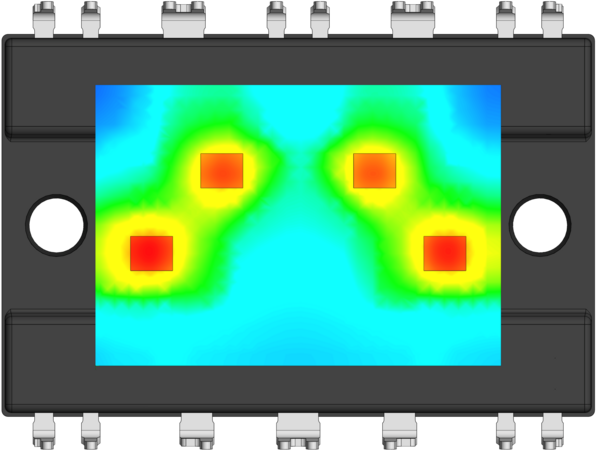

③Reduction in Temperature Rise

Suitably distributed chip placement can suppress heat interference.

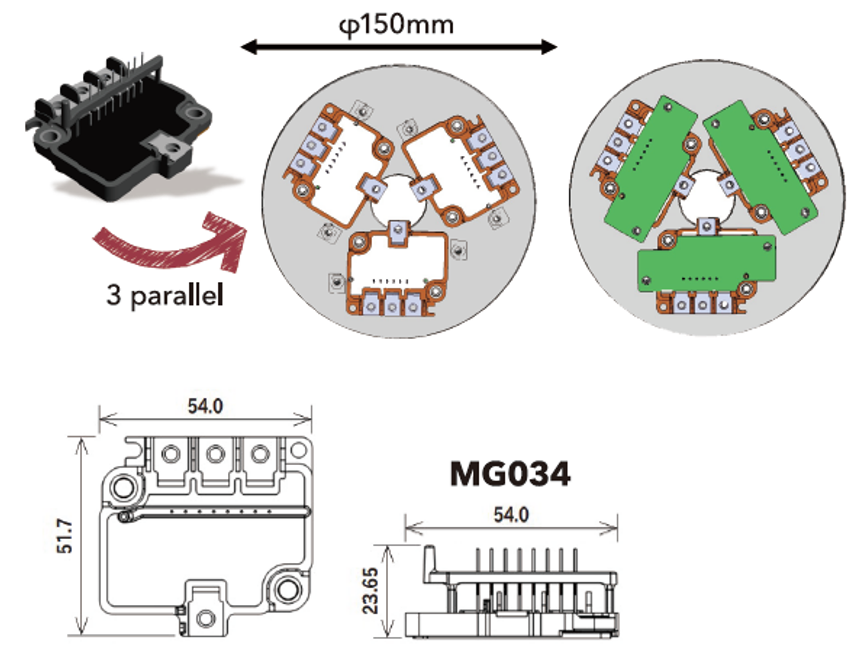

Motor Driven Transfer Power Module『MG031』

Features

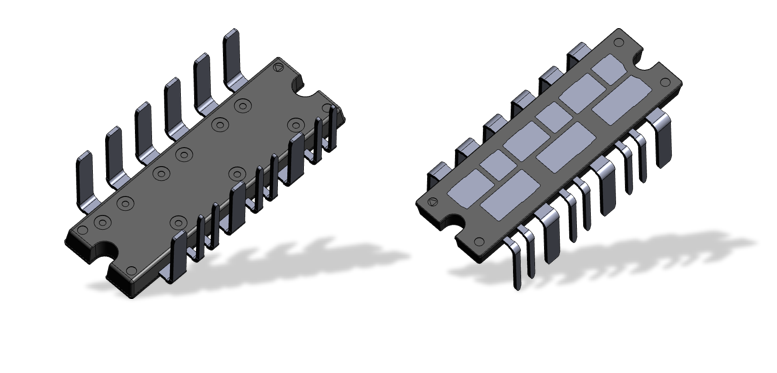

①Compactness and High Integration

Integrating the driver section into a power module can not only reduce mounting area but also simplify part mounting process.

②Mounting Area Reduced by 60%, ECU Volume Reduced by 35%

Our power module contributed to achieving substantially smaller and lighter unit than that made of existing discrete MOSFETs by integrating them into the power module.

③Available for Automotive

Our power module has been used for Automotive EPSs, DC/DC converters, electronic braking, Electric bicycle and Industrial equipment, etc.