Development History(DC/DC converter)

In the latter half of the 1990's, countries all over the world began implementing initiatives aimed at reducing environmental burden as a response to global warming, and as part of this, automobile manufacturers also began developing automobiles which were more environmentally friendly.

Our company specializes in power supply products, and utilized the semiconductor, power supply, and vehicle installation technologies we developed throughout the 2000's to develop DC/DC converters which were installed in vehicle applications.

DC/DC converters are required to convert voltage from secondary high voltage batteries (lithium ion batteries: LiB, etc.) which drive motors, to 12 V batteries which drive ECUs, headlights, and other electrical devices, and we have launched series, after series of vehicle installation power supplies on the market in order to respond to demand for various environmentally friendly vehicle types (EV, P-HEV, HEV, FCV).

Although there are differences in the regulations of each country at present, we promote the development of the downsized, lightweight, and highly efficient DC/DC converters with our company's strengths.

Development Technology

Circuit technologies and control technologies which achieve higher efficiency and lower noise.

1. Partial resonance full bridge type

The main circuit configuration for this power supply uses a partial resonance full bridge type which achieves zero voltage switching operation with a smaller number of components. This contributes to greater fuel efficiency for automobiles by working to reduce switching loss of internal components and setting the conversion efficiency to its highest point in the range of actual use.

-

-

- Circuit configuration block diagram

-

-

-

- Main FET module

-

-

-

- Efficiency characteristics

-

2. Performance improvement through digital control

Control for DC/DC converter power control and communications is all fully digital (DSP). Optimal power feed system control is achieved through optimal control of circuit operation, improved functionality, power supply monitoring, safe design, and communication with higher ECU, which were not able to be achieved with previous analog technologies.

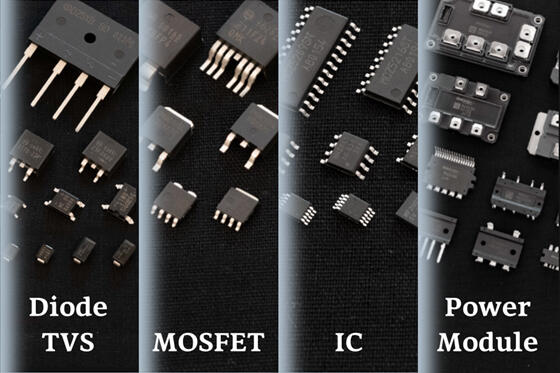

3. Use of internally manufactured components

DC/DC converter main circuit components (primary FET module, transformer, secondary synchronous rectification FET module, output choke) are optimally designed parts based on individual power supply specifications produced in-house by Shindengen's Electronic Device Division Group and Magnetic Part Department. These parts are also mounted in aluminum die-cast cases in order to further improve air cooling and water cooling heat dissipation performance.