The Shindengen Group is committed to reducing the environmental impact and mitigating the environmental risks of its business activities in areas including global warming countermeasures, chemical substance reduction, waste reduction, and water resource and biodiversity conservation.

The following are examples of key activities among the initiatives we undertook in FY 2023.

Reduction in CO2 emissions

The Shindengen Group is endeavoring to reduce its CO2 emissions to achieve the FY 2030 environmental targets it announced at the same time as its Environmental Vision 2050.

The Shindengen Group in Japan participates in the Carbon Neutrality Action Plan formulated and promoted by the electric and electronic machine industries as a voluntary action plan, and to improve its energy intensity improvement rate by a yearly average of 1% or more and reduce its CO2 emissions by 46% compared to FY 2013, it is engaged in activities to improve the energy efficiency of its production processes and improve equipment, and it undertakes various measures to reduce CO2 emissions in its business activities.

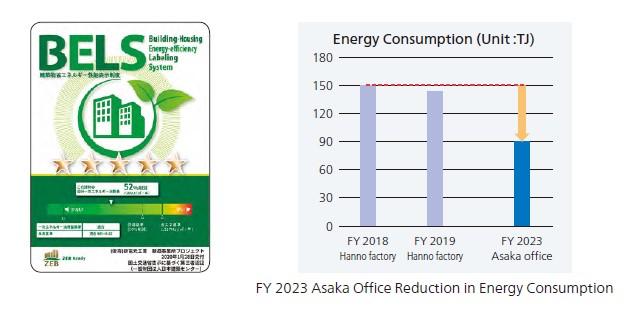

The Asaka Office, which opened in 2021, has significantly reduced its energy consumption by consolidating the functions of business divisions and departments that were previously spread across the Otemachi Head Office and multiple buildings at the Hanno Factory into a single building, and by adopting a ZEB Ready building*.

*The Asaka Office acquired ZEB Ready certification as an advanced building approaching ZEB (Net Zero Energy Building), the highest rank in the Building-Housing Energy-Efficiency Labeling System (BELS).

Adoption of Electricity Derived from Renewable Energy

10,297 MWh in FY 2022 ⇨ 25,836 MWh in FY 2023 (Group)

•Shindengen Electric Manufacturing Co., Ltd. Asaka Office: 100% (FY 2022– )

•Okabe Shindengen Co., Ltd.: 50% ⇨ 100% (May FY 2023– )

•Akita Shindengen, Higashine Shindengen, Shindengen Three E (FY 2023– )

Adoption of Solar Power Generation Systems

・Shindengen India (FY 2023– )

・Okabe Shindengen Co., Ltd. (planned adoption in FY 2024)

Primary Challenges for Reducing CO2 Emissions

The Shindengen Group Companies: Primary challenge (FY 2023)

Initiatives on CO2 Emission Reduction Activities

With the support of Chiang Mai University, Lumphun Shindengen is working to reduce greenhouse gas emissions. Chiang Mai University's support is part of the greenhouse gas emission reduction activities at the Northern Region Industrial Estate where Lumphun Shindengen is located. This support primarily consists of briefly explaining how to visualize (i.e., calculate) greenhouse gas emissions from business activities and how to proceed with this process.

After inspecting the factory, Chiang Mai University provided guidance on issues and potential improvements in the factory facilities, and also provided guidance on the calculation of greenhouse gas emission reductions and the amount and recovery period of investments in these reductions.

Lumphun Shindengen has shared this guidance with relevant departments within the company and is promoting activities to reduce greenhouse gas emissions.

• Major reduction measures proposed by Chiang Mai University

(1) Upgrading air conditioning equipment

(2) Preventing compressed air leakage

(3) Installing solar powered lights around the factory perimeter

(4) Revising the factory work schedule

• Total anticipated reduction

(1) Amount of electricity saved: 1,742.7 MWh/year

(2) CO2 emission reduction: 784.3t-CO2

Contributing By Providing Environmentally Friendly Products

Aiming to achieve decarbonization and sustainability across society, as targeted by the Paris Agreement, the Shindengen Group provides environmentally friendly products as a proactive way of reducing greenhouse gas emissions during product use and attempting to solve issues in line with the international sustainable development goals (SDGs) initiative. The Group agrees with measures promoted by local communities to mitigate and adapt to climate change effects and proactively supports related activities. Refer to the Initiatives for the SDGs for details.

Greenhouse Gas Emissions (Scope 1, Scope 2, Scope 3)

Shindengen Electric Manufacturing Co., Ltd. calculates the GHG Protocol's Scope 1, Scope 2, and Scope 3

emissions based on greenhouse gas emissions-related data collected from the value chain.

Initiatives to Reduce Plastic

The Shindengen Group in Japan aims to be environmentally friendly by replacing or reducing the use of plastic, and each company has set specific targets for reducing plastics, which it is working towards.

Shindengen Electric Manufacturing Co., Ltd. held an internal briefing session mainly on the Act on Promotion of Resource Circulation for Plastics which went into effect in 2022. This enabled them to align the awareness of all employees on plastics and obtain understanding for future initiatives.

Meanwhile, individual Group companies in Japan have set targets that suit them, such as reducing the amount of packaging, selecting recycling operators to implement continued recycling, and increasing the recycling rate through improved sorting.

Shindengen Three-E is working to optimize the disposal of waste plastic. Until now, plastics were delivered to recycling companies for thermal recycling (i.e., for reuse as fuel) without being separated into their respective materials. However, after repeated discussions with recycling companies, we have implemented the separation of waste pallets and trays (used to transport and package purchased parts and materials) with identifiable plastic materials. By separating these plastics into their respective materials, we can now sell them to recyclers while also contributing to the realization of a recycling-oriented society through the effective use of resources in material recycling (i.e., reuse as materials).

Initiatives to Manage Chemical Substances

The Shindengen Group is working to achieve its stated environmental objective of “engaging in sustainable activities to protect people and the environment through appropriate management of information about chemical substances contained in products.”

The Chemical Substance Management Subcommittee (consisting of Shindengen Electric Manufacturing Co., Ltd.’s Asaka Office and domestic Group companies) regularly shares with Group companies the latest information regarding domestic and international laws and regulations, studies green procurement standards, manages information about chemical substances contained in products, and manages chemicals used in-house.