Manufacturing bases for Power Management Electronics

The overseas bases of our Power Unit business are mainly located in ASEAN and India, where there are large motorcycle markets, and we are engaged in local production and sales.

Okabe Shindengen serves as the mother factory for the Power Unit business, providing production technology, equipment technology, and manufacturing guidance to overseas bases in ASEAN, China, and India. In addition, we have established a BCP system in which production sites complement each other, and we have established regular opportunities for exchange among sites to improve productivity through information sharing.

Furthermore, each overseas base is also engaged in flexible production, such as local procurement of structural materials and shortening of production lead times.

Shindengen India

|

Address(Head office) |

Plot No.283/2, Bommasandra-Jigani Link Road, Jigani Industrial |

|

Establishment |

Augast 2012 |

|

Site area |

20,000 square meters |

|

Main production items |

Regulators, ECUs |

Shindengen India (SIP) expands our business to India in 2012 and established a production factory. India's two-wheel vehicle market reached 10.8 million units in 2010 and exceeded 20 million units in 2017, supporting the lives of a country of 1.4 billion people as an important means of transportation.

SIP mainly manufactures regulators and ECU(Electronic Control Unit) for two-wheel vehicle. In 2018, in order to meet the growing demand for two-wheel vehicle, we expanded our factory by 2.5 times compared to the original size and began producing ECUs that comply with BS6 (Bharat Stage 6) exhaust gas regulations.

We have already started producing PCU (Power Control Unit) “DU012” for two-wheel EV since 2023 and continue to provide products that contribute to India's environmental measures.

Shindengen Indonesia

|

Address |

Kawasan Greenland International Industrial Center(GIIC), |

|

Establishment |

November 2001 |

|

Site area |

35,258 square meters |

|

Main production items |

ECUs, Regulators |

Shindengen Indonesia was established in 2001 amid the growth in the number of motorcycles sold in Southeast Asia in the 2000s.

The country's motorcycle market, which exceeded 3 million units in 2004, reached 8 million units in 2011. In order to meet the growing demand, the company moved to a new factory in 2016.

In 2004, a function for controlling fuel injection to reduce emissions was added to the ACG starter ECU, which controls the system by integrating the starter motor drive circuit and battery charging circuit into one, and has grown to become a mainstay product in the Power Unit business. Even today, more than 5 million ECUs are produced each year, mainly in Southeast Asia, and Shindengen Indonesia is one of the important bases that produces 60% of these.

We are expanding our activities that are rooted in the local community, such as by providing an Islamic prayer room in the company.

Shindengen Thailand

|

Address |

60/58 Moo 19 Soi Nava Nakorn 13 Klongnueng, |

|

Establishment |

December 1987 |

|

Site area |

23,520 square meters |

|

Main production items |

ECUs, Regulators, ECUs for automotives, Inverters |

Shindengen Thailand was the first overseas production base for our group, starting operations in 1987. At first, the company manufactured semiconductors, but in 1988 it began manufacturing Power Unit to meet the growing demand for motorcycles in Thailand.

In the wake of the severe flooding that hit Thailand in 2011, Shindengen Thailand was affected by water rising above floor level, and we had to take measures to ensure alternative production both in Japan and overseas. This prompted us to strengthen our BCP measures, including the introduction of a company-wide system that enables us to monitor the production status at each site and build a system that can respond quickly in an emergency.

Today, it manufactures electrical products for motorcycles, automobiles, and generators, and it also has a technical department that has established a development system to meet the needs of motorcycle manufacturers in ASEAN countries, playing a leading role in the group's ASEAN bases.

Shindengen Vietnam

|

Address |

Plot No. D-4 Thang Long Industrial ParkII,Nguyen Van Linh Commune, Hung Yen Province, Vietnam |

|

Establishment |

September 2010 |

|

Site area |

30,800 square meters |

|

Main production items |

ECUs, Regulators |

Shindengen Vietnam was established in 2010 as the fourth overseas production base for Power Unit.

In 2011, the year after the company was established, when Thailand was hit by major flooding, the Shindengen Vietnam factory, which had been in operation for less than a year, played an important role as an alternative factory for the Shindengen Thailand factory, which had been flooded.

In 2014, the company also became the first overseas group company to begin manufacturing Power Unit for automobiles. A production and quality system different from that for motorcycles was established overseas, and this became the cornerstone for the production of automobiles at other overseas bases.

We received an award in 2021 from the Vietnam Labor Union for being an excellent company that provides a good working environment and welfare benefits for its workers, and we are also working to create a comfortable working environment.

Guangzhou Shindengen

|

Address |

No.83, Xinzhuang 2nd Road, |

|

Establishmet |

June 1994 |

|

Site area |

24,815 square meters |

|

Main production items |

Regulators, CDIs |

In 1992, China revised its economic policy from a planned economy to a socialist market economy, and as deregulation and regional opening accelerated the attraction of foreign capital, our group established Guangzhou Shindengen Electronic in Guangzhou City, Guangdong Province, following on from Shanghai Shindengen in 1994. The company was initially established as a joint venture with a local company, but in 2001 it became a wholly-owned subsidiary.

While supplying parts to motorcycle manufacturers throughout China, from the second half of the 2000s, the company added additional processing of its own power semiconductors, which are mounted in Power Unit, and has shifted to production that is not limited to the local Chinese market, such as shipping to ASEAN bases.

Okabe Shindengen

|

Address |

342-1 Hongou, Fukaya City, Saitama 369-0214, Japan |

|

Establishment |

July 1985 |

|

Site area |

54,576 square meters |

|

Main production items |

DC/DC converters, Regulators |

When Okabe Shindengen was first established in 1985, it manufactured a wide range of products, including electrical components for motorcycles, power supply components, and solenoids. Currently, it is the core base for the Shindengen Group's Power Unit business, which accounts for the majority of the group's sales, and it manufactures products such as DC/DC converters for environmentally friendly vehicles.

In addition, it accumulates production technology cultivated in the process of stepping up from development to prototyping and mass production, and it plays the role of the mother factory for the Power Unit business, providing guidance on production technology, equipment technology, and quality control to overseas bases in ASEAN, China, and India that mass-produce and locally sell products for motorcycles.

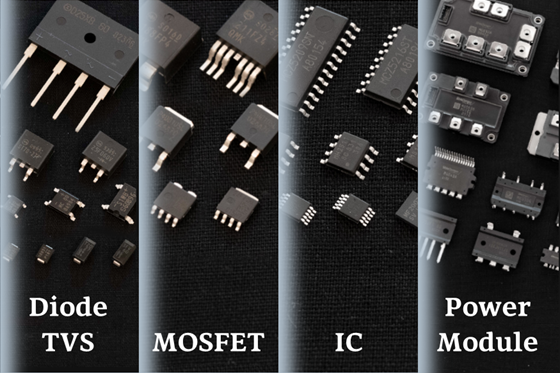

Manufacturing bases for Semiconductors

In the Power Device business, the front-end processing is mainly performed in Japan, while the back-end processing is handled by domestic and overseas group companies, creating an integrated production system within our own group. We have introduced an IoT-based production management system that collects production data from both domestic and overseas production sites and manages the operating status of equipment, which helps us to prevent equipment breakdowns and efficiently produce a wide variety of products on the same production line.

Since the launch of the Vehicle Quality (VQ) Promotion Project in 2005, we have been working to build manufacturing lines that meet the quality requirements of the automotive market and to improve design and manufacturing quality. The results of this work have been highly evaluated by automotive manufacturers, and have led to strengthening of the relationship of trust with customers, as evidenced by the awards received. This has led to semiconductors for automotive use now accounting for around 40% of the Power Device business.

Lumphun Shindengen

|

Address |

Northern Region Industrial Estate(I-EA-T Free Zone) |

|

Establishment |

March 1991 |

|

Site area |

37,007 square meters |

|

Main production items |

Semiconductors |

Lamphun Shindengen was established in 1991 in the suburbs of Chiang Mai in northern Thailand to take over the semiconductor production of Shindengen Thailand in order to expand overseas semiconductor production.

In the early 1990s, dealing with the strong yen was a challenge, as the yen hit 79.25 yen to the US dollar in April 1995. As the ratio of semiconductor products exported overseas began to exceed 30%, the importance of Lamphun Shindengen increased as the company expanded its overseas production.

Production of power modules began in 2018. As the demand for power modules for automotive and industrial equipment applications increases, this is also contributing to the strengthening of the cost competitiveness of our products.

Shindengen Philippines

|

Address |

120 Excellence Avenue Cor. Quality Drive Carmelray, Industrial Park 1, |

|

Establishment |

March 1995 |

|

Site area |

28,351 square meters |

|

Main production items |

Semiconductors |

In the early 1990s, the issue of how to respond to the strong yen, which reached a record high of 79.25 yen to the US dollar in April 1995, was a challenge, and as the ratio of overseas exports of semiconductor products in the group began to exceed 30%, we announced the policy of “Double overseas sales, triple overseas production” to strengthen our overseas expansion. In response to this, Shindengen Philippines was established in 1995 to take over the affiliated company in the Philippines, to which the manufacturing of semiconductors had been outsourced.

It is mainly responsible for the back-end processing of diodes, and plays an important role in our group by achieving both cost competitiveness and high quality.

The company also makes efforts in local community activities, such as sponsoring an annual "Fun Run" and donating money to nearby schools based on the distance run by participants, and participating in tree-planting activities organized by the local Carmelray community.

Akita Shindengen

|

Address |

114-2 Aza Kamiyachi, Oora, Yurihonjyo City, Akita 015-8558, Japan |

|

Establishment |

July 1970 |

|

Site area |

106,800 square meters |

|

Main production items |

Seimconductors |

Akita Shindengen, established in Honjo City (now Yurihonjo City), Akita Prefecture in 1970, expanded its Oora Plant to its fifth building in 1991 in response to increasing demand for semiconductors, and in 1996 and 1999, it opened two buildings at its Asuka Plant, which handles front-end processing.

In addition to manufacturing, we also have development functions, and we are promoting development that is suitable for manufacturing from the perspective of those on-site.

The Vehicle Quality (VQ) Promotion Project, which was launched in 2005, reviewed the manufacturing lines to meet the requirements of the automotive market, and worked to improve design and manufacturing quality, moving away from the previous focus on manufacturing for the consumer market. The results of these efforts have been recognized in the form of awards from automotive manufacturers, and the plant is now a major production base for semiconductors for automotive applications.

Higashine Shindengen

|

Address |

5600-1 Kou, Ooaza Higashine, Higashine City, Yamagata 999-3701, Japan |

|

Establishment |

July 1981 |

|

Site area |

66,000 square meters |

|

Main production items |

Semiconductors |

Higashine Shindengen was established in Higashine City, Yamagata Prefecture, in 1981, and in 2005 it expanded its clean rooms to include a fourth building. In addition to handling the front-end processing for semiconductors such as MOSFETs, it also manufactures IC products and power modules.

We have been expanding our automotive products by refining our quality control technology, obtaining TS16949 certification in 2008 and IATF16949 certification in 2018.

Manufacturing bases for Power Systems & Solutions

Shindengen Three E

|

Address |

3-1, Ashikariba, Hannou City, Saitama 357-0013. Japan |

|

Establishment |

Juy 1991 |

|

Site area |

33,939 square meters |

|

Main production items |

Telecommunication Power Supplies, EV chargers |

Shindengen Three E was established in 1991 by acquiring the shares of Sanko Electric Co., Ltd., to which we had been outsourcing the production of our power supply products, and the company's name was changed to the current one in 1992.

In addition to manufacturing rectifiers for telecommunications, in recent years we have also been involved in the production of power conditioners for solar power generation, as well as quick chargers and AC chargers for electric vehicles, and we are producing products that contribute to the prevention of global warming and the effective use of renewable energy by making use of our compact, high-efficiency power supply technology.