Before 1949

Shindengen's predecessors can be traced back to the electric stove manufacturer Dengensha, which was established in 1935. In addition to electric stoves, the company was also involved in the production of selenium rectifiers; however Dengen Kogyo Co., Ltd. was established as a dedicated selenium rectifier manufacturer in 1944 in order to meet the demand of military for the Pacific War.

After the end of the war, driven by the happenings at the time, Dengen Kogyo resumed production of selenium rectifiers. Later, in addition to manufacturing rectifying elements and direct current power supplies to satisfy public and private sector demand, the company shifted to private sector business through a variety of initiatives including development of a method for processing silkworm silk using ultrashort waves. However, the introduction of synthetic fibers caused demand for raw silk to drop, and Dengen Kogyo, which had over 1,308 employees at the time, was faced with potential bankruptcy and forced to undergo corporate restructuring in 1949.

Shindengen Electric Manufacturing Co., Ltd. was then established in 1949 to succeed the company's rectifier division. The new company began with 5 million yen in capital and 465 employees transferred from Dengen Kogyo.

1949 to 1979

The advent of silicon diodes

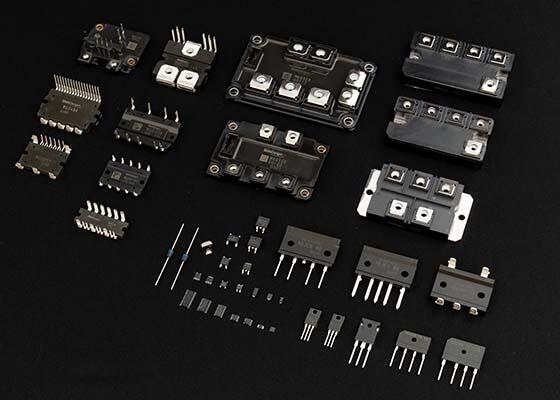

Shindengen's core product semiconductors

At the time of its establishment, selenium rectifiers were Shindengen's core business, so when semiconductors using germanium, silicon, and other materials were later developed, the company worked to apply these technologies to rectifier applications /rectification in Shindengen's semiconductor products.

Shidengen's long history of power semiconductor research and development began when alloy-type germanium transistors were introduced in 1952, and Shindengen worked to perfect alloy-type germanium transistors for rectification in 1957. Silicon thyristors were also introduced in 1957, and Shindengen then also completed thyristor prototypes in 1960, and began sale of 16A/400V products in 1961.

At present, in addition to discrete semiconductors such as MOSFET and IGBT, we also manufacture other power semiconductor related products, including monolithic IC, hybrid IC, power modules, and more.

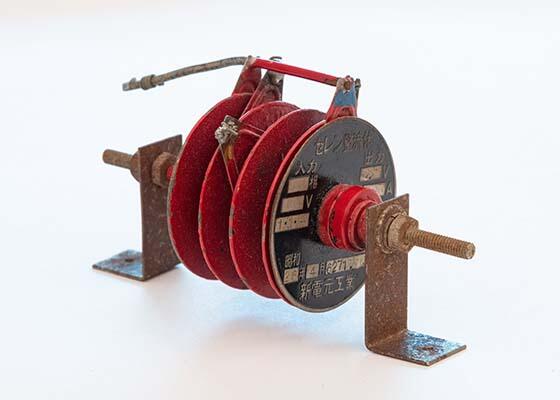

Development of selenium rectifiers for telephone exchanges

The invention of a patented short-circuit prevention method for selenium rectifier elements greatly improved the reliability of elements developed by Shindengen, significantly contributing to expansion of the company's business. In 1952, the Japanese telecommunications system was transferred to the control of Nippon Telegraph and Telephone Public Corporation (present day NTT) which drove a rapid acceleration in the installation of telecommunications equipment within Japan. Seizing on this opportunity, Shindengen successfully sold A-3000-1 selenium rectifiers to the Hamacho telephone exchange in 1955. This was the beginning of the establishment of selenium rectifiers as power supplies for telephone exchanges, and they still form the basis of the telecommunications power supply business today.

A selenium rectifier developed in 1950’s

The advent of glass passivation technology

Semiconductor passivation protects semiconductor elements from dust, humidity, ions, and other external environment factors, and is an extremely important layer which has a significant impact on the characteristics and reliability of semiconductor products. Shindengen has long used glass developed in-house for this purpose in order to achieve improved product quality and longer product service life. For example, Shindengen needed to transport chips to an assembly plant operating in the Philippines in 1976. In order to maintain the durability to withstand the long transportation times, the chips were covered with high quality glass produced in-house to make them more resistant to chemical and mechanical effects, and supported the growth of our business. At present, this glass passivation technology is used for not only semiconductors, but also for Shindengen's power management electronics and other products. Shindengen continues to work on improvements to our glass production in order to improve both the functionality and quality of our company's products.

1980 to 1999

Overseas expansion

In the 1990's, in addition to Japan, Shindengen also aggressively expanded overseas including in ASEAN countries with growing two-wheel vehicle markets, and also increased exports from its electronic device business.

Shindengen Thailand (SDT) was launched as the Shindengen Group's first overseas production base in 1988. At the time of its establishment, the company carried out production of semiconductors, but later also began manufacturing of power management electronics to satisfy growing two-wheel vehicle related demand in Thailand, growing into the group's core base for the ASEAN region. Then, in 1991, Lumphun Shindengen (LSD) was established in the suburbs of Chiang Mai in northern Thailand to take-over SDT's semiconductor production to increase overseas production of semiconductors.

In the early 1990's, the company had to deal with issues stemming from the strong yen, which reached a record high of 1 USD = 79.25 yen in April 1995. As the ratio of semiconductor products exported overseas began to exceed 30%, the importance of LSD and Shindengen Philippines (SDP), which was established in 1995, began to grow as bases for strengthening Shindengen's overseas development.

SDT (top) and LSD (bottom)

Expansion of semiconductor product lineups

In September 1979, an IC and MOSFET research and development department was established and then completed development of the monolithic IC used in Shindengen's power management electronics and power supplies in 1982. Then, in 1988 the 500V MOSFET and motion driver IC (MTA and MTB series) products began being offered. Around this time, in the diode field, bridge diodes were developed which incorporated SIP (Single In-line Package) structure and AC/DC separation structure technologies, and the business continued to expand in order to satisfy continually diversifying semiconductor needs.

The introduction of the core power management electronics product

ECU for two-wheel vehicles

In 1983, Shindengen developed regulators which controlled lamp voltage and battery voltage, and since then regulators have grown to become a major pillar of the car electronics business through achievements such as securing an 80%* share of the global market for regulators for two-wheel vehicles.

In 1979, the CDI (Capacitor Discharge Igniter) was developed and mass production of CDI for compact motorcycles began. Then in 1986, CDI with build-in converters were also introduced. Shindengen's CDI products have established a predominant position in the market through improvements to start-up performance and other features.

In the 2000's, FI control functions were added to two-wheel vehicles in order to reduce emission gases, with start-up motor control, charging control, and ignition/injection control coming to be carried out by a single unit, and Shindengen developed ECU which allow for idling stops and achieve lower gas emissions and lower fuel consumption. These ECU then grew into new core products that would join regulators and CDI.

Driven by these core products, and with the expansion of the two-wheel vehicle markets in Thailand, Vietnam, Indonesia, and other ASEAN markets, Shindengen's car electronics business has made great progress.

*According to internal studies.

2000 to 2020

Rapid growth in power conditioners for solar power generation systems

power conditioner

As focus on issues such as global warming countermeasures, and exhaustion of energy resources continued to grow, Japan introduced the feed-in tariff system (FIT) for renewable energy and began promoting the adoption of renewable energy. In 2011, Shindengen developed a bidirectional 2kW inverter unit for home electricity storage systems. In the same year, the company also developed high frequency insulation type PCS (power conditioner) and entered the renewable energy market. The company has since grown its sales and captured a top-class share of the industrial PCS market.

Strengthening development of value-added products

The 2000's saw the bursting of the IT bubble, the Lehman Shock, and other events which impacted the company's business environment. The company used this as an opportunity to shift its core field from the private sector semiconductor products that had been Shindengen's focus up until then, to products for vehicle applications, which require a high degree of reliability, and worked on strengthening initiatives aimed at improving quality in everything from design to manufacturing. As a result, vehicle application products have grown to 40% of the electronic device business sales at present, becoming the core of the business. The company also established an independent power module division in 2012 as the needs for modularization grew as a result of the trend toward device downsizing and functional advancement. Not only are products which integrate the circuit technologies and mounting technologies developed by Shindengen sold independently, they are also incorporate into Shindengen's power management electronics and power supply products, and continue to support our business as drivers of growth for each of these product categories.

In addition, in the power management electronics field, we have also expanded our lineup of products with embedded software, and developed high efficiency step-down voltage DC/DC Converters for HEV and FCV; developed idling-stop compatible ECU for two-wheel vehicles and began mass production in ASEAN regions, and otherwise continue to expand the fields of application for environmentally-friendly products. In 2011, we also developed 50kW quick chargers for EV which achieve high efficiency and lower noise based on our high reliability rectifier technologies cultivated in the telecommunications field. Since then, we have continued to grow with the domestic EV charging infrastructure market, including advancing to development of products with a maximum output of up to 150kW.

Power module (left) and EV quick charger (right)

Renewal of the Shindengen logo and corporate brand

Previous diode motif logo (left)

New Shindengen logo (right)

On July 1, 2017, we renewed our brand logo from the diode motif based logo that has long been familiar since it was registered as a trademark in September of 1951.

When creating the new corporate logo, we first reconsidered the "essence and character" of Shindengen, then we created a new philosophy system incorporates the philosophy system we have maintained up until now; consisting of the management philosophy, corporate mission, and action agenda; with the addition of the pledge "Listen closely, look ahead, and create a future of value" which states how to realize those ideals, and the new brand statement "New power. Your power.".

Opening of the Asaka Office

The Hanno Factory has long carried out research and development and business management functions as a core facility for the Shindengen Group.

However, over its 70 year history, the building has become worn out to a degree that could no longer be maintained, so it was decided to construct a new office in Asaka City. The Asaka Office was thus born based on the four concepts of "consolidate functions and improve productivity", "advanced environment", "comfort and ease of working", and "safety and security". By consolidating the functions of the Otemachi head office and Hanno Factory, and integrating buildings by division, the office aims to promote the development of products suited to a new era and contribute to society, paving the way for the future taking the first step on a new path.

Asaka Office

Timeline

| Year | Month | History |

| 1949 | August | Established as Shindengen Electric Manufacturing Co., Ltd. and took over the semiconductor and rectifier departments of Dengen Electric Manufacturing Co., Ltd. |

| 1953 | July | Opened the Osaka office in Osaka City (currently Osaka Branch). |

| 1958 | June | Shares listed on stock exchange (started selling as Tokyo Stock Exchange OTC securities). |

| 1961 | October | Listed as a second-section company on the Tokyo Stock Exchange. |

| 1964 | April | Opened the Nagoya office in Nagoya City, Aichi Prefecture (currently Nagoya Branch). |

| 1966 | April | Established Coma Electronics Industry Inc. (currently merged with Shindengen Three E Co., Ltd.). |

| 1968 | March | Established Yamanashi Electronics Co., Ltd. |

| November | Moved to first section of Tokyo Stock Exchange. | |

| 1969 | November | Established Nippon Vendor Net Co., Ltd. |

| 1970 | April | Established Azuma Electronics Co., Ltd. |

| July | Established Akita Shindengen Co., Ltd. | |

| 1975 | February | Added “electrical work and telecommunication work” to corporate purposes. |

| 1976 | March | Established Shindengen Menpatsu Co., Ltd. (previously Shindengen Device Commerce Co., Ltd., merged with Shindengen Electric Manufacturing Co., Ltd.). |

| November | Established Shindengen Shoji Co., Ltd. (merged with Shindengen Electric Manufacturing Co., Ltd.). | |

| 1978 | November | Established Yamagata Shindengen Co., Ltd. (currently merged with Shindengen Three E Co., Ltd.). |

| 1981 | July | Established Higashine Shindengen Co., Ltd. |

| 1985 | July | Established Okabe Shindengen Co., Ltd. |

| 1986 | November | Established Taiwan representative office in Taipei City, Taiwan Province, ROC. |

| 1987 | February | Established Shindengen America Inc. in California, USA. |

| 1988 | January | Established Shindengen Seiki Co., Ltd. (merged with Shindengen Electric Manufacturing Co., Ltd.). |

| Established Shindengen (THAILAND)Co., Ltd in Bangkok City, Thailand. | ||

| 1989 | January | Made Sanko Denki Co., Ltd. an affiliated company by increasing its capital (currently Shindengen Three E Co., Ltd.). |

| September | Acquired Magnaquest Ltd. in London, UK (currently Shindengen UK Ltd.). | |

| December | Established Shindengen Kumamoto Techno Research Co., Ltd. | |

| Established Shindengen Maintenance Co., Ltd. (merged with Shindengen Electric Manufacturing Co., Ltd.). | ||

| Established Shindengen Enterprise Co., Ltd. | ||

| 1990 | March | Established Shindengen Keisoku Inc. (merged with Shindengen Electric Manufacturing Co., Ltd.). |

| June | Established Shindengen Singapore Pte Ltd. in Singapore. | |

| 1991 | March | Established Lumphun Shindengen Co., Ltd. in Chiang Mai, Thailand. |

| 1992 | July | Established the Seoul office in Seoul, Korea. |

| 1993 | March | Established Shindengen Logistic Co., Ltd. (currently merged with Higashine Shindengen Co., Ltd.). |

| 1994 | April | Established Guangzhou Shindengen Electronic Co., Ltd. in Guangzhou City, PRC. |

| May | Established Shanghai Shindengen Communication Equipment Co., Ltd. in Shanghai City, PRC. | |

| October | Established Shindengen (H.K.) Co., Ltd. in Hong Kong, British Dependent Territory (currently PRC). | |

| 1995 | March | Established Shindengen Philippines Corp. in the Province of Laguna, Philippines. |

| 2001 | April | Invested in Napino Auto & Electronics Ltd. in Haryana, India, and made it an affiliated company. |

| November | Established PT. Shindengen Indonesia in West Java, Indonesia. | |

| 2002 | February | Established Shindengen Mechatronics Co., Ltd. |

| 2006 | February | Established Shindengen Sensor Device Co., Ltd. |

| 2007 | April | Nippon Vendor Net Co., Ltd (affiliated company) acquired 100% of the shares of Chuo Keibi Hosho Co., Ltd. |

| December | Opened the Bangkok office in Bangkok City, Thailand. | |

| 2009 | May | Established Shindengen (SHANGHAI) Electric Co., Ltd. in Shanghai City, PRC. |

| 2010 | September | Established Shindengen Vietnam Co., Ltd in Hung Yen Province, Vietnam. |

| 2012 | August | Established Shindengen India Private? Ltd. in Karnataka, India. |

| 2014 | August | Established Shindengen Lao Co., Ltd. in Champasak Province, Laos. |

| 2019 | November | Acquired all the shares of Hermes Systems Inc. |

| 2021 | April | Established Asaka Office in Asaka City, Saitama, Japan |